When equipping high-pressure pumps and heavy-duty machinery, the choice of Gasoline Drive Power holds significant weight. It directly impacts not just the immediate operational efficiency of the equipment but also its long-term reliability and serviceability. A power unit that fails to align with the equipment's needs may lead to frequent breakdowns or unnecessary energy consumption, making careful selection a foundational step for smooth operations.

The Significance of Power Matching

Power matching is more than a technical detail—it is a core factor that shapes the overall performance of high-pressure pumps and machinery. If the gasoline-driven power is insufficient for the equipment's demands, the engine will operate under constant strain. This strain can manifest in slow operation, inconsistent output, and accelerated wear of internal components, ultimately cutting short the equipment's usable life. On the other hand, a power unit larger than required may not deliver the expected efficiency. It tends to consume more fuel while operating at less-than-ideal load levels, increasing operational costs over time. Achieving a balanced match ensures that the engine operates within its optimal range, supporting both performance and economy.

Foundational Step: Assessing Operational Requirements

The selection process starts with a comprehensive analysis of the equipment's operational context. First, clarify the specific type of machinery in use—whether it is a high-pressure cleaning pump, industrial transfer pump, construction vibrator, or hydraulic power unit. Each type carries distinct load patterns; for example, some may require steady power output, while others experience fluctuating loads during operation.

Next, pinpoint the power needs by referencing the equipment manufacturer's specifications. This includes both the continuous power required for regular operation and the temporary peak power needed during startup or when handling heavy loads. Work cycle patterns also demand attention: will the engine run for extended periods without interruption, or will it alternate between active and idle phases? Additionally, environmental factors cannot be overlooked. Higher ambient temperatures can reduce engine cooling efficiency, while increased elevation affects air density, both of which influence the actual power output of the gasoline drive unit.

Evaluating Engine Specifications and Construction

Once operational demands are clear, focus shifts to evaluating the engine itself. A key consideration is the engine's duty cycle rating, which differentiates between units designed for occasional use and those built for prolonged commercial service. Engines intended for commercial applications often incorporate durable features such as cast iron cylinder sleeves, reinforced bearings, and heavy-duty crankshafts, all of which enhance their ability to withstand continuous operation.

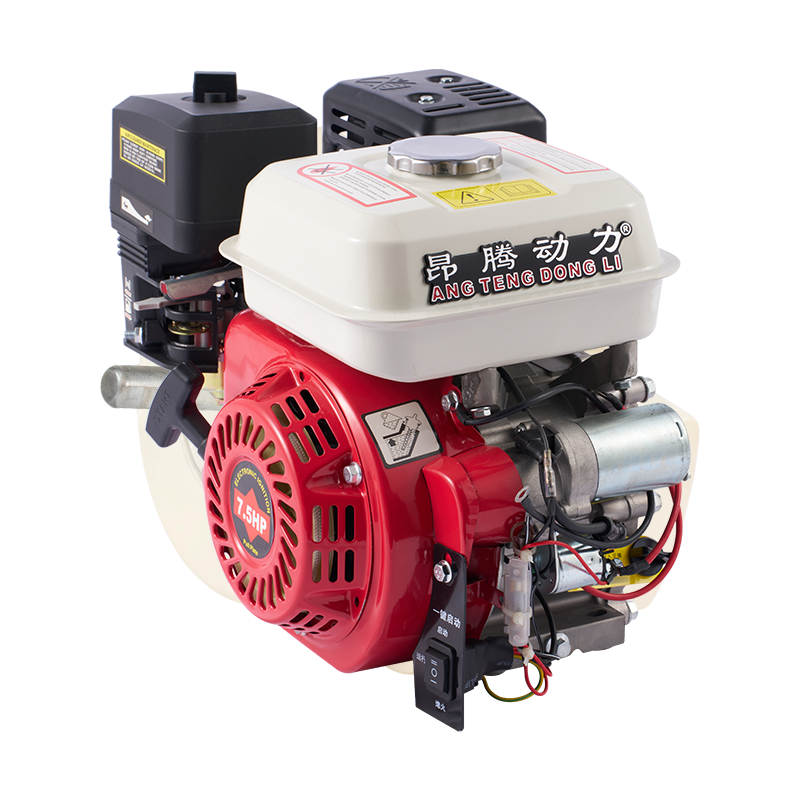

In terms of design, Overhead Valve (OHV) technology is widely recognized as a reliable choice for industrial settings. Compared to traditional side-valve designs, OHV engines offer improved fuel combustion, leading to better fuel efficiency and reduced emissions. They also tend to run more smoothly and generate less noise, contributing to a more manageable working environment. Modern engine management systems, though adding a layer of complexity, can enhance operational stability by regulating fuel delivery and ignition timing according to load changes, ensuring consistent performance across varying conditions.

A Practical Checklist for Selection

To simplify the decision-making process, a structured checklist can be invaluable: Confirm the equipment's continuous and peak power requirements, expressed in both kilowatts (kW) and horsepower (HP); Determine the appropriate engine duty cycle based on the expected daily runtime and operational intensity; Verify the presence of OHV technology and assess whether advanced engine management features align with operational needs; Check the engine's performance adjustments for high-altitude or high-temperature environments, ensuring it can maintain output under local conditions; Evaluate the manufacturer's after-sales support, including warranty coverage and the availability of replacement parts in the local market.

Prioritizing Matched Performance

Selecting a gasoline-driven power unit is an investment in the equipment's overall productivity and longevity. Cutting corners by choosing an underperforming or ill-suited unit often leads to more frequent downtime and higher maintenance costs in the long run. By systematically comparing the equipment's requirements against the engine's specifications and construction quality, operators can secure a power unit that delivers consistent performance, reduces operational disruptions, and supports stable, cost-effective operations over an extended period.

English

English русский

русский Français

Français Español

Español عربى

عربى