The reliable operation of equipment, whether for industrial, agricultural, or transportation purposes, depends heavily on the health of its engine. For both gasoline and diesel power plants, understanding the lifecycle of components and the practices for their use is fundamental to maintaining productivity and managing operational activities.

Gas & Diesel Engine Accessories: When should they be replaced?

Engine accessories are vital components that support the core functions of the engine, and their timely replacement is key to avoiding unexpected interruptions. While each part has its own service life, there are common indicators that can guide replacement decisions.

For fuel system components, such as fuel filters and injectors, a decline in engine performance is a primary signal. This may present as difficulty starting, a noticeable loss of power, or an increase in fuel consumption. In diesel engines, a clogged fuel filter can rough idling, while in gasoline engines, a failing fuel pump may cause the engine to hesitate under load. Air intake accessories also provide clear signs. A dirty air filter will often result in reduced acceleration and a darker color to the exhaust smoke, indicating an overly rich fuel mixture.

Ignition and electrical accessories, particularly in gasoline engines, show symptoms when they are nearing the end of their service life. Worn spark plugs can cause engine misfires, a rough idle, and challenges during cold starts. The battery is another critical accessory; a slow engine crank, especially in cooler weather, often suggests that the battery can no longer hold a sufficient charge and should be replaced to prevent a complete failure. For cooling system components like belts and hoses, visual inspections are very effective. Cracks, fraying, or a glazed appearance on serpentine belts are signs they should be exchanged. Similarly, coolant hoses that feel soft, brittle, or show visible bulging should be replaced proactively. Adhering to the manufacturer's recommended service intervals for these accessories provides a reliable framework for maintaining consistent engine operation.

Heavy-Duty Diesel Engine Parts: How can they be fully utilized?

Heavy-duty diesel engines are designed for demanding applications, and fully utilizing their parts involves practices that promote service life and operational efficiency. This approach centers on proactive care and precise operational control.

The foundation of full utilization is a consistent and high-quality maintenance routine. This includes using engine oil and filters that meet or exceed the manufacturer's specifications and adhering strictly to oil change intervals. Clean oil is essential for lubricating critical components like turbochargers and piston rings, which directly influences the engine's longevity and performance. Furthermore, maintaining a clean and unrestricted air intake system is crucial. A high-quality air filter that is changed regularly protects internal parts from abrasive contaminants, allowing them to operate as designed for their full intended lifespan.

Proper operational practices also contribute significantly to part utilization. Allowing the engine to reach its ideal operating temperature before applying heavy loads helps ensure even expansion and lubrication. Conversely, implementing a cool-down period after extended high-load operation is beneficial for the turbocharger, allowing it to slow down gradually and extend its service life. Utilizing modern engine management systems to their full potential is another key strategy. Monitoring engine data can help operators maintain running conditions that are within efficient parameters, avoiding prolonged periods of excessive load or low RPM that can premature wear. Finally, ensuring that the engine is properly tuned and that fuel injection timing is accurate helps parts work together harmoniously, which supports overall durability and fuel economy.

What are the characteristics of diesel engine parts?

Diesel engine parts are engineered for durability and high compression, which results in several distinct characteristics. Understanding these traits is helpful for operators and maintenance personnel.

Robust Construction and Weight:

To withstand the high cylinder pressures inherent in diesel combustion, core components like the engine block, cylinder heads, and crankshaft are built with significant material strength. This results in a greater overall mass and weight for the engine assembly, contributing to its notable longevity and solid feel.

Operational Noise and Vibration:

The high compression ratio required for ignition creates more forceful combustion events compared to other engine types. This fundamental aspect of their operation often increased noise levels and vibration, which are managed through specialized engine mounts and insulation in modern designs.

Cold-Weather Starting Considerations:

The compression-ignition process relies on heat generated by compressing air, which can be more difficult to achieve in low temperatures. This characteristic often necessitates additional components like glow plugs or block heaters to ensure reliable engine starting in colder climates.

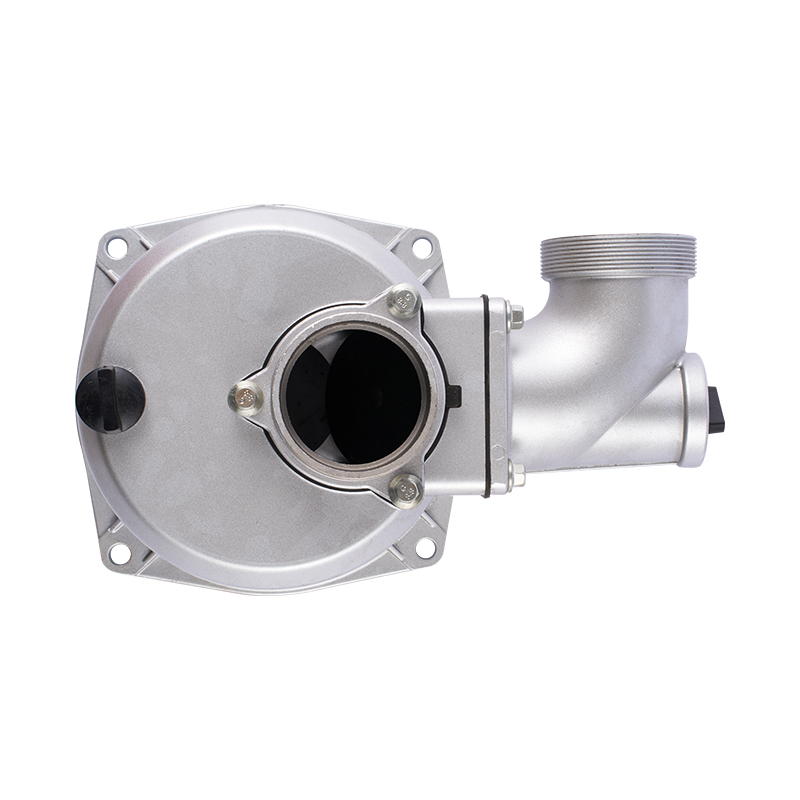

High-Precision Fuel System:

The fuel system in a diesel engine is a high-precision assembly. Components like fuel injectors and injection pumps are manufactured to fine tolerances to deliver fuel at very high pressures. This demands a high level of cleanliness during maintenance and often requires specialized knowledge and tools for proper service.

Initial Procurement Consideration: The advanced materials and precise manufacturing required for key components, such as fuel injection pumps and turbochargers, can involve a higher initial procurement cost compared to parts for other engine types. This is often viewed as an investment in the component's extended service life and performance.

English

English русский

русский Français

Français Español

Español عربى

عربى